G.AL® C250

highest precision –

extremly low tension

Medium Strength Precision Milled Plate

Alloy: EN AW-5083 (AlMg4,5Mn0,7 – 3.3547)

Type of alloy:non heat-treatable

Temper: 03

Surface:two surfaces precision milled, roughness Ra 0.4 µm, foiled on both sides

- Excellent machining and anodising capabilities

- excellent flatness

- extremely low residual stress

- superior corrosion resistance

- very good homogeneity

- excellent dimensional tolerances

- high strength

The two sides precision machined G.AL® C250 precision plate with protective foil was developed from almost universally-applicable alloy EN AW-5083 (AlMg4.5Mn0.7). Rolling ingots are used for production, which have a fine-grained, homogeneous structure with only low microporosity created in a modified casting process and specific heat treatments. The result are precision plates which are distinguished by very uniform flatness, high strength and good technical anodising properties.

Applications

Jig-making

Thanks to excellent flatness and very narrow tolerances, gauges of all kinds can be realised with G.AL® C250 and put into use within a very short time.

Fixture construction

Elaborate thickness processing is completely eliminated when using G.AL® C250. Due to the excellent corrosion resistance, a material mix normally does not damage the metal.

Packaging industry

The excellent technical anodising capability of G.AL® C250 allows this material to be used in a variety of applications as base and support plates in plant areas where visual demands are only conditionally required.

Automation technology

Even rotary indexing tables with a diameter of up to 2,160 mm and coordinate plates can be produced easily without distortion with the extremely low-stress, flat and parallel G.AL® C250.

Mechanical engeneering

Base and ground plates, side and back walls can be realised safely and economically in a short amount of time with G.AL® C250, even at high degrees of machining and with intricate contours.

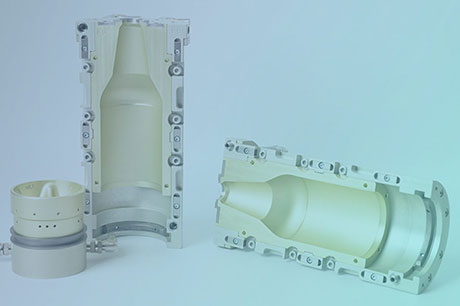

Model and mould-making

For applications as mounting and model base plates, G.AL® C250 is the perfect choice due to its narrow tolerance regarding flatness, parallelism, thickness and good strength.

To avoid any unwanted surprises when removing the protective film from the precision plates, they must never be exposed to sunlight. The natural rubber adhesive of the film is not UV resistant and becomes brittle within a short time, and the protective film can then only be removed with great effort.