ALPLAN® 7075

finally milled on both sides –

for extremly precesion

High-strength precision rolled plate

Alloy: 7075 (AlZn5,5MgCu)

Type of alloy: heat treatable

Temper: T651

Surface:two surfaces precision milled, roughness Ra 0.4 µm, foiled on both sides

- very high strength

- narrow tolerances of thickness and flatness

- very good machinability

- very good hardness

- two sides precision machined surface

In certain applications, the use of higher-strength cast plates is not sufficient; high-strength rolled plates must be used. However, the problem with rolled plates is the wide toleration of thickness and flatness, which results in extremely complex processing. Precision rolled plate ALPLAN® 7075 from alloy 7075 (AlZn5.5MgCu), finely milled on both sides and covered with protective foil, provides users with a semi-finished product which drastically reduces the time required for machining.

Applications

Toolmaking

In, for example, cutting and stamping technology, ALPLAN® 7075 is widely used for anvil caps and punch retainers.

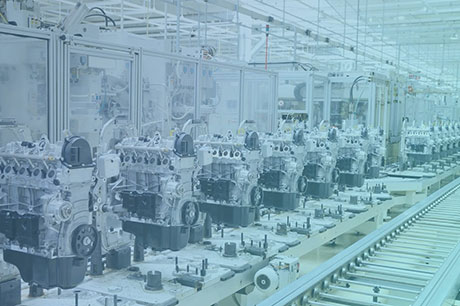

Device construction and mechanical engineering

Heavily-loaded transfer and coordinate plates can be made in very short amounts of time with ALPLAN® 7075.

Packaging and printing industry

Base and support plates that are exposed to high stress due to structural or functional reasons are one of the many fields of application of ALPLAN® 7075.

Automation technology

In automation, for example rotary indexing tables, can often be economically produced from this semi-finished product due to the uniform flatness of ALPLAN® 7075.

Expert tip

If components show a very high degree of machining and they must be highly accurate, there can be a problem with warping when using rolled plates. This risk can be minimised if the processed component is subjected to stress relief annealing after the roughing operation at 140 ° C for 2 hours and only then is finished.