G.AL® C330 DYNAMIC

special material for

highly sensitive applications

Higher Strength Plate

Alloy: EN AW-7021 (AlZn5,5Mg1,5)

Type of alloy: heat treatable

Temper:solution heat treated, quenched, artifically aged, T79

Surface:six-sides sawn, roughness Ra <15 µm

- free of microporosity, diffusion resistance

- very high strength and hardness

- very good elongation properties

- very good machinability

- excellent damping characteristics

- first rate polishability

- ideally suited for applications under dynamic loads

Special material G.AL® C330 DYNAMIC is an advancement of the proven G.AL® C330R from alloy EN AW-7021 (AlZn5.5Mg1.5) . The outstanding features of higher-strength aluminium plate G.AL® C330 DYNAMIC sawn on all sides – absolutely free of microporosity, isotropy, very good stretching values – are generated by special casting parameters, elaborate post-processing and multi-level heat treatment.

Applications

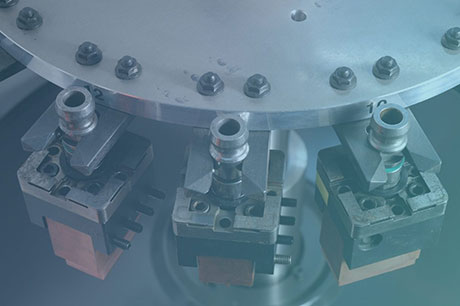

Hydraulics

Conventional Al cast plates cannot be used in hydraulics because of the microporosity. Due to the excellent stretching properties and absolute lack of pores up to pressures of about 250 bar, control blocks from G.AL® C330 DYNAMIC have proven their worth better than those made of ultra-high- and high-strength rolled plates.

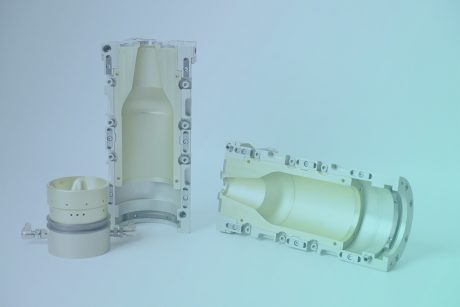

Mould-making

In a direct comparison of pre-series injection moulds for the automotive industry (plastic: PP) made from high-strength EN AW 7010 rolled plates, G.AL® C330 DYNAMIC showed itself to be clearly superior: 40% less time required for the preparation of the mould, 17% longer life. The reason for this is in the very good machinability and polishing, low stress and isotropic (not directionally-dependent) properties of G.AL® C330 DYNAMIC.

Drive technology

Gearboxes, whether for assembly lines, sliding units or actuating / clock units must sometimes be able to absorb high forces at small wall thicknesses, for example, professional camcorders or thermal imagers must also be guaranteed a high shock resistance. Degrees of machinability of more that 90% at times re not uncommon. Difficult with rolled plates, easy to implement with G.AL® C330 DYNAMIC.

Mechanical engineering and special machine engineering

In mechanical engineering, tool carriers, force redirection devices (fork heads), bearing blocks, etc. are often made from distortion-prone rolled plates in a very costly and elaborate process. Conventional cast plates are unsuitable for such applications. With G.AL® C330 DYNAMIC, a material is available to designers which combines low-stress properties, high strength and high hardness due to the excellent stretching properties of G.AL® C330 DYNAMIC.

Isotropic properties are of great importance for a whole range of applications materials, for example in hydraulics. Isotropic and non-microporous G.AL® C330 DYNAMIC fully meets such demands; faulty manufacturing is therefore ruled out because directional material properties were not taken into account.