UNIDAL®

precision rolled plate

High-strength precision rolled plate

Alloy: EN AW-7019 (AlZn4Mg2Mn)

Type of alloy: heat treatable

Temper: T651

Surface:two surfaces precision milled, roughness Ra 0.4 µm, foiled on both sides

- good weldability

- high strength

- narrow tolerances of thickness and flatness

- very good machinability

- good anodising capability

- two sides precision machined surface

Precision rolled plate UNIDAL® made form alloy EN AW-7019 (AlZn4Mg2), finely milled on both sides and covered with protective film, is characterised by a narrow tolerance of flatness and thickness and has only relatively low residual stresses. The good anodising and welding capability opens up a wide range of applications for this product.

Applications

Installation technology

Base and support plates can also be made of UNIDAL® when they have difficult contours.

Device construction and mechanical engineering

Due to the good weldability yet high strength of UNIDAL®, a variety of welded structures are made from this material.

Printing industry

UNIDAL® is mainly used for printing plates in this sector. The good anodising qualities also enable very smooth functional surfaces.

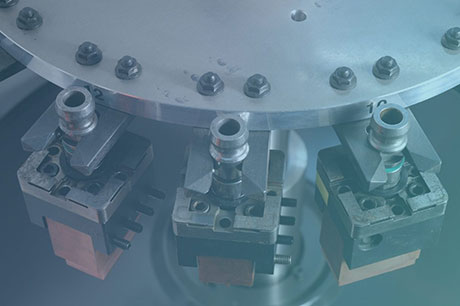

Automation technology

Higher-loaded transfer and coordinate plates are often made from UNIDAL®, particularly if anodisation must satisfy aesthetic requirements and medium-strength cast plates are not sufficient.

Expert tip

If components show a very high degree of machining and they must be highly accurate, there can be a problem with warping when using rolled plates. This risk can be minimised if the processed component is subjected to stress relief annealing after the roughing operation at 140 ° C for 2 hours and only then is finished.