G.AL® Precision machined plates

our concept of precision

Our G.AL® Precision Machined Aluminium Cast Plates reach extremely high standards in:

- thickness tolerance

- flatness

- parallelism

- surface roughness

In addition to this general “dimensional precision” we are focussing on basic values such as the physical, metallurgical and technological properties.

The result is a highly reproducible

maximum of internal and external precision

for each single plate and each cutting.

The basis for our G.AL® Precision Machined Aluminium Cast Plates are aluminium raw materials which were specially developed, based on our know-how and experience.

Our range of G.AL® Precision Machined Aluminium Cast Plates:

G.AL® C250

highest precision with extremly low tension G.AL® C250

G.AL® C250 ELOX PLUS

for optimal results in anodizing

G.AL® C250 ELOX PLUS

G.AL® C330

highest precisions at high strength

G.AL® C330

After a special heat-treatment and bypassing the conventional rolling process our aluminium slabs are divided up into plates on special band saws.

It is a special designed sawing process with the focus not bring any stresses in the material. The result are extremely stress relieved sawn plates with a fine-grained, homogeneous micro structure and high strength values without any directional influences on the properties.

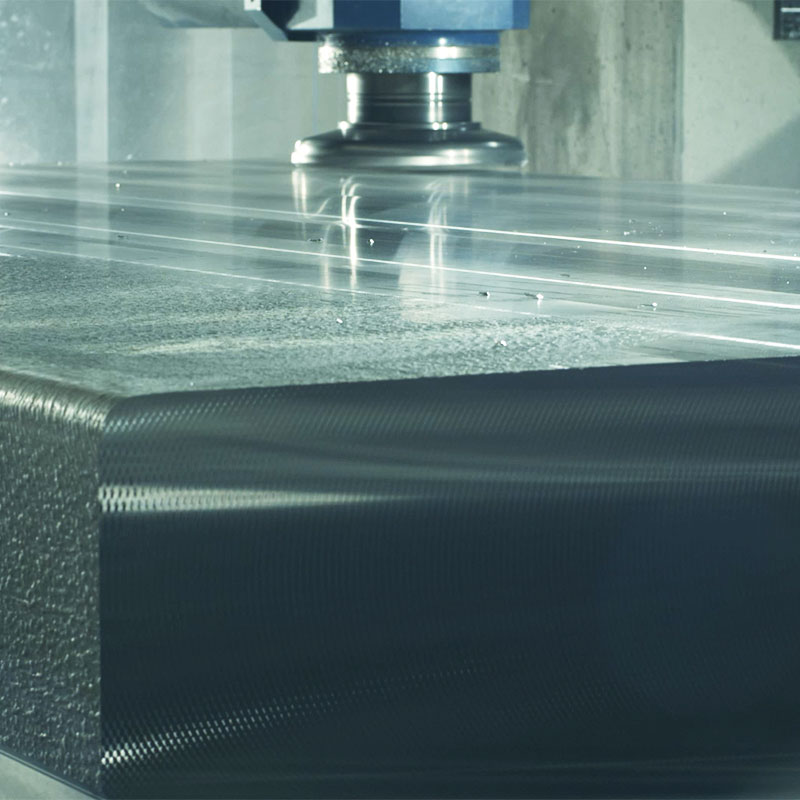

On stable portal milling machines with more than 2 m wide milling heads we create precision, accuracy and the unique surface characteristic for our G.AL® plates. Afterwards each plate is inspected concerning its thickness, flatness, surface roughness and finally PVC– coated for surface protection.

The available range of precision plates covers all areas of application where precision in combination with higher strength values is required, such as construction of jigs and fixtures, all kind of gauges, tables, indexing and transfer plates, special purpose machines and all parts that justify the name “precision part”.