UNIDAL®

Přesná válcovaná deska

Vysoce pevná přesná válcovaná deska

Slitina: EN AW-7019 (AlZn4Mg2Mn)

Typ slitiny: vytvrditelná

Povrch: T651

Stav materiálu: oboustranně frézovaný,hloubka drsnosti Ra 0,4 µm

- Dobrá svařitelnost

- Nízké tolerance tloušťky a rovinnosti

- Nízké tolerance tloušťky a rovinnosti • Dobrá eloxovatelnost

Přesná válcovaná deska vyrobená ze slitiny EN AW-7019 (AlZn4Mg2), UNIDAL®, která je jemně frézována po obou stranách a je pokryta ochrannou fólií, se vyznačuje nízkou tolerancí rovinnosti a tloušťky a vykazuje relativně nízké vnitřní pnutí. Díky dobré eloxovatelnosti a svařovatelnosti má tento produkt široké spektrum použití.

Aplikace

Montážní technika

Z materiálu UNIDAL® lze vyrobit i základní a základové desky s obtížnými tvary

Konstrukce přípravků a strojů

Díky dobré svařitelnosti a zároveň vyšší pevnosti materiálu UNIDAL® je z těchto desek vyráběna celá řada svařovaných konstrukcí.

Tiskařský průmysl

Materiál UNIDAL® je zde používán převážně na tiskové desky. Díky dobré eloxovatelnosti lze navíc dosáhnout velmi hladkých funkčních povrchů.

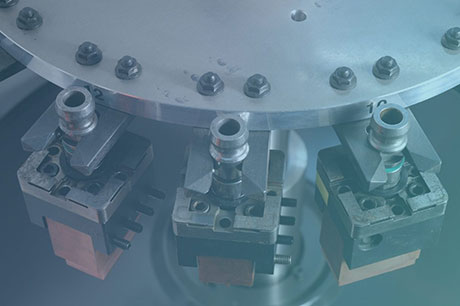

Automatizační technika

Přenosové a souřadnicové desky s vyšší zátěží jsou často vyráběny z materiálu UNIDAL®, a to zejména tehdy, když je požadován vizuálně dobrý eloxovaný vzhled, avšak středně pevné lité desky nepostačují.

Expert Tip

Vykazují-li díly velmi vysoký stupeň obrábění a přitom musí být vysoce přesné, může při použití válcovaných desek docházet k potížím s deformací. Toto nebezpečí lze minimalizovat, když je obráběný díl po hrubování při 140 °C podroben po dobu 2 hodin žíhání za účelem odstranění vnitřního pnutí a teprve poté dokončen.