Die Aluminium Experten

GLEICH Aluminium

Unsere Produkte

G.AL® Präzisionsplatten

Produktauswahl

G.AL® C250

höchste Präzision mit einem Minimum an Eigenspannungen

G.AL® C250 G.AL® C250

G.AL® C250 ELOX PLUS

für optimale Anodisierungsergebnisse

G.AL® C250 ELOX PLUS G.AL® C250 ELOX PLUS

G.AL® C330

hervorragende Präzision bei hohen Festigkeiten

G.AL® C330 G.AL® C330

G.AL® gesägte Platten

Produktauswahl

G.AL® C210R

allseitig gesägte Aluminium Gussplatte – für eine Vielzahl von Anwendungen z.B. im Formenbau geeignet

G.AL® C210R kaufen G.AL® C210R

G.AL® C330R

höherfeste, allseits gesägte Gussplatte – besonders formstabil und spannungsarm

G.AL® C330R kaufen G.AL® C330R

G.AL® DYNAMIC

Produktauswahl

G.AL® C210 DYNAMIC

Spezialprodukt für dynamische Belastungen – frei von Mikroporosität

G.AL® C210 DYNAMIC G.AL® C210 DYNAMIC

G.AL® C330 DYNAMIC

höherfeste DYNAMIC Variante für pneumatische und hydraulische Anwendungen

G.AL® C330 DYNAMIC G.AL® C330 DYNAMIC

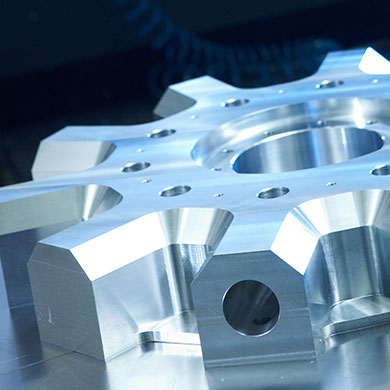

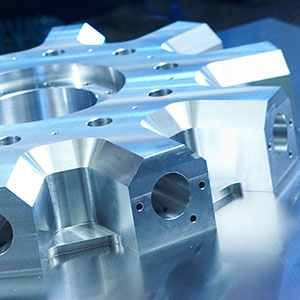

Der Markenname G.AL® steht für extrem verzugsarme, formstabile und homogene Aluminium-Präzisions- und Formenbauplatten mit gleichbleibend guter Qualität.

Unsere Leistungen

Platten und Zuschnitte

Platten und Zuschnitte

- Plattengrößen bis 2.160 x 4.000 mm

- individuelle Zuschnitte ab 30 x 50 mm

- maximale Dicke bis zu 1.070 mm

- Platten und Zuschnittstoleranzen entsprechend der Produktdatenblätter der einzelnen Produkte

Ronden und Konturzuschnitte

Ronden und Konturzuschnitte

- bandgesägt bis zu 2.200mm + Wasserstrahl geschnitten bis zu 2.160mm

Konturzuschnitte

- Laserstrahl geschnitten bis zu 10 x 2.160 x 4.000 mm + Wasserstrahl geschnitten bis zu 220 x 1.570 x 6.000 mm oder 220 x 2.160 x 4.000mm

- Bandgesägt bis zu 600 x 2.160 x 4.000 mm

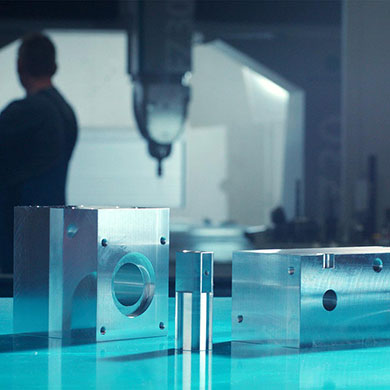

CNC Fertigung

CNC Fertigung

Bei uns kaufen Sie direkt beim Hersteller und haben einen Ansprechpartner von der Produktion bis zum fertigen Zeichnungsteil.

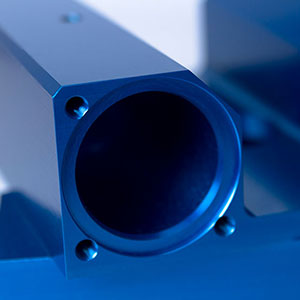

Oberflächenbehandlung

Oberflächenbehandlung

Die Oberflächen von Aluminium-Bauteilen können durch eine Vielzahl von Verfahren veredelt werden.

Ohne einen zusätzlichen Oberflächenschutz, der in der Mehrheit durch verschiedene Anodisierungs-Verfahren eingestellt wird, sind hochwertige Oberflächen kaum dauerhaft vor mechanischen, thermischen und chemischen Belastungen zu schützen.

Zeichnungsteile nach Ihren Wünschen

Seit über 40 Jahren beschäftigen wir uns mit Aluminium. Neben der Produktion von spannungsarmen Aluminium-Gussplatten verfügen wir über eine eigene CNC-Fertigung, die sich komplett auf Aluminium spezialisiert hat.

So können wir in unseren Bearbeitungszentren auf das Produkt-Know-How zurückgreifen und optimal auf den Werkstoff abgestimmte Werkzeuge und Bearbeitungsverfahren wählen.

Perfekte Optik!

Neben der technischen Veredelung werden Oberflächenverfahren wie das Anodisieren oder Pulverbeschichten zunehmend auch zur optischen Veredelung von Bauteilen angewendet. Wir stellen uns dieser Herausforderung und können Ihnen durch die Kombination unseres Know-Hows aus den Bereichen Werkstoffkunde und Oberflächenverfahren die bestmöglichen Resultate bieten.

Aluminium Know-How

Profitieren Sie von unser Aluminium Erfahrung. Sie wissen nicht genau, welche Legierung Sie einsetzen sollen? Was ist die ideale Schnittgeschwindigkeit bei unterschiedlichen Legierungen? Warum darf ich Gussplatten nicht vor dem Eloxieren beizen? Senden Sie uns gerne Ihre Fragen, die Aluminium-Experten von GLEICH Aluminium helfen Ihnen gerne weiter!

GLEICH Aluminium Wissen

faszinierendes Projekt aus G.AL® C250 ELOX PLUS

Bei der Anwendung unseres Werkstoffs G.AL® C250 ELOX PLUS durch die Seitz + Strenger GmbH & Co.KG ist ein Tisch entstanden, der nicht nur funktional, sondern auch ästhetisch beeindruckend ist.

Ist das eigentlich noch Alu ?

Industrien mit den höchsten Anforderungen stützen sich zu Recht auf den leicht zu verarbeitenden Werkstoff Aluminium. Auch die Medizintechnik würde ohne den Einsatz von Aluminium nicht in dem heute bekannten Maße funktionieren.

Wärmebehandlung ohne Einsatz von Erdgas

Wie ein deutscher Hersteller weltweit einen Alleingang macht und dabei zur Referenz für Qualität wird