G.AL® C210R

all rounder for

medium strength applications

Medium Strength, Six-Sides Sawn Plate

Alloy: EN AW-5083 (AlMg4,5Mn0,7 – 3.3547)

Type of alloy: non heat-treatable

Temper: O3

Surface: six-sides sawn, roughness Ra <15 µm

- extremely low-stress properties

- very good dimensional stability

- very good corrosion resistance

- available up to 1.100 mm thickness

- six-sides sawn surface

A medium-strength aluminum plate, G.AL® C210R is the all-rounder of aluminum materials. The G.AL® C210R sawn on all sides is characterized by extremely low-stress properties, dimensional stability and excellent homogeneity over the entire ingot cross section. Based on alloy EN AW-5083 (AlMg4.5Mn0.7), G.AL® C210R is corrosion-resistant to a large extent and can be technically anodized very well. With an slab thickness of up to 1.100 mm and width up to 2.200 mm, large-scale projects can be also be realized.

Applications

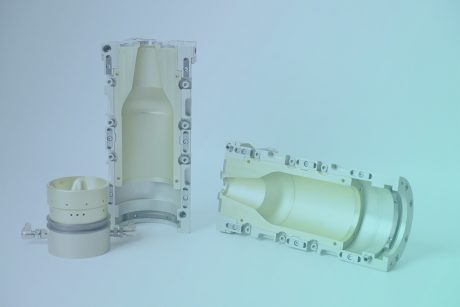

Mold-making

In mold-making, G.AL® C210R is the perfect choice for deep drawing, foaming and casting molds and prototype molds in plastic injection molding, just to name a few, thanks to the good machinability.

Optical industry

Many manufacturers of optical devices and equipment take advantage of the good technical anodizing properties of G.AL® C210R to produce functional and appealing surfaces.

Medical technology

The extremely low-stress properties of G.AL® C210R ensures distortion-free components, such as the housing for dialysis pumps and similar equipment, even at degrees of machining of > 90%.

Food industry

In much of the food industry, G.AL® C210R is the preferred product for a variety of applications because of its food safety according to EN 602-2004.

Plant engineering, chemical industry

Due to the excellent corrosion resistance of G.AL® C210R, this material is also used in areas with critical atmosphere and liquids.

Laser technology

The silicon outgassing dreaded in laser technology is avoided through the use of G.AL® C210R due to the low silicon content and the very homogeneous structure.

Components with degrees of machining >85-90% often cause a lot of trouble in production. If up-cut milling is not executed and synchronous milling is performed instead, you will get excellent work results in conjunction with the extremely low-stress G.AL® C210R.