EN AW-6082

high resistance to stress corrosion tracking

Medium-strength rolled plate

Alloy: EN AW-6082 (AlMgSi1 – 3.2315)

Type of alloy: heat treatable

Temper: T6/T651

Surface:mill-finished or brush-finished

- very good anodizing capability

- high resistance to stress corrosion cracking

- very good weldability

- good corrosion resistance

- good thermal conductivity

Alloy EN AW-6082 (AlMgSi1) is situated in the upper segment of medium-strength rolled plates, has very good resistance to stress corrosion cracking (SCC) in addition to high thermal conductivity.

Any further questions?

Applications

Welded constructions

Due to good weldability, rolled plate EN AW-6082 can be found everywhere in device construction and conveyor technology as a welded structure.

Shipbuilding

Because of its good resistance to seawater, rolled plate EN AW-6082 is used for many applications above and below the deck of ships and yachts.

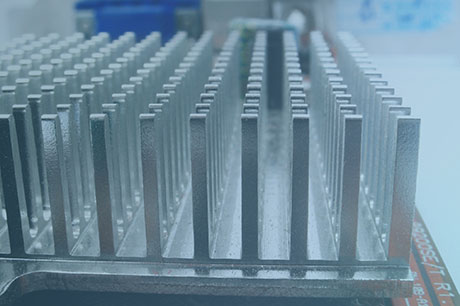

Cooling technology and vulcanisation

The high thermal conductivity of EN AW-6082 makes it beneficial in refrigeration and in the rubber industry for shortening the cycle times of molds, among other things.

Food industry

Rolled plates made of EN AW-6082 are safe in contact with food in accordance with EN 602:2004. For this reason, this material is used in a variety of applications in industrial plants of the food industry.

Expert tip

The tolerances for thickness and flatness are very wide in rolled plates. For example, a 20 mm thick plate has a thickness tolerance of ± 0.03 in. The flatness is specified as a percentage and is calculated longitudinally (always in the rolling direction!) and in width (always transverse to the rolling direction!). A 0.8 in. thick slab in format 59.8 x 118.9 in. may vary by 0.2% = 0.24 in. in width from the flatness.

In comparison, G.AL® C250 in 0.8 in. thickness: thickness tolerance: ± 0.004 in., flatness: 0.005 in.